2026 Boratas BLJ110

2026 Boratas BLJ110

السنة

السنة

٢٠٢٦

حالة المعدة

حالة المعدة

جديد

نظرة عامة

الوصف

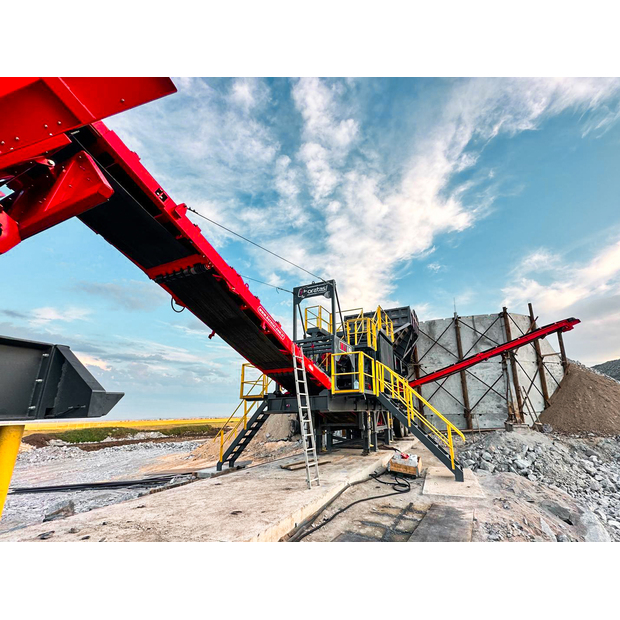

Boratas Wheeled Mobile Jaw Crusher BLJ110 is a mobile primary crushing unit designed for robust material reduction in demanding applications such as quarrying, mining, and recycling. Combining reliable jaw crushing technology with a wheeled transport design, the BLJ110 delivers consistent throughput and operational flexibility on a variety of job sites.

Its versatile design supports quick relocation, fast setup, and efficient primary crushing of limestone, granite, basalt, and similar hard materials. The BLJ110 wheeled chassis enables simplified transport between locations, reducing downtime and logistics costs for contractors and quarry operators.

The machine can be integrated into larger wheeled mobile crushing and screening plants, as a two-chassis plant with a cone crusher or as a three-chassis plant with a vertical shaft impact crusher. Which makes it suitable for multi-stage processing systems where compact efficiency and portability are important.

Electric Drive Configuration

The BLJ110 is designed primarily for electric operation and is intended to be connected to an external power source. Upon request, an optional diesel generator can be supplied to support projects requiring independent operation or temporary power solutions.

Technical Specifications

• Capacity: 100-300 tph

• Max. Feed Size: 850 mm

• Jaw Opening: 1100 x 850 mm

• Weight: 52,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

******************************************************************

Standard Features:

• High-capacity jaw crusher unit

• Wheeled mobile chassis

• Hydraulic folding conveyors

• PLC-based control system

• Electric operation

• Gear motor-driven conveyors

• Feed hopper and grizzly vibro feeder

Optional Features:

• Magnetic metal separator

• Hardox-lined hopper

• Automatic lubrication system

• Dust suppression system

Key Features and Differentiators

1. High-Capacity Primary Crushing

The BLJ110 is engineered to deliver consistent primary crushing performance for hard and abrasive stone, ensuring stable throughput and reliable operation in quarrying and mining tasks.

2. Wheeled Mobility

Wheeled design enables fast relocation and setup between job sites, reducing transportation and commissioning time for contractors managing multiple locations.

3. Flexible Integration

The machine can be combined with additional crushers or screens to build multi-chassis mobile plants tailored to project requirements.

4. Operator-Friendly Design

The BLJ110 features intuitive controls, easy maintenance access points, and a straightforward interface to improve operator efficiency and reduce service time.

5. Durable Construction

Built with heavy-duty components, the BLJ110 withstands challenging site conditions and long operational hours while minimizing downtime and maintenance requirements.

6. Enhanced Safety Features

Boratas prioritizes operator safety. The BLJ Series wheeled jaw crusher units are equipped with emergency stop systems, protective guards, and robust structural elements to ensure a safe working environment on site. In addition, the hydraulically adjustable jaw opening further enhances operational safety and control.

Boratas Wheeled Mobile Jaw Crusher BLJ110 is a mobile primary crushing unit designed for robust material reduction in demanding applications such as quarrying, mining, and recycling. Combining reliable jaw crushing technology with a wheeled transport design, the BLJ110 delivers consistent throughput and operational flexibility on a variety of job sites.

Its versatile design supports quick relocation, fast setup, and efficient primary crushing of limestone, granite, basalt, and similar hard materials. The BLJ110 wheeled chassis enables simplified transport between locations, reducing downtime and logistics costs for contractors and quarry operators.

The machine can be integrated into larger wheeled mobile crushing and screening plants, as a two-chassis plant with a cone crusher or as a three-chassis plant with a vertical shaft impact crusher. Which makes it suitable for multi-stage processing systems where compact efficiency and portability are important.

Electric Drive Configuration

The BLJ110 is designed primarily for electric operation and is intended to be connected to an external power source. Upon request, an optional diesel generator can be supplied to support projects requiring independent operation or temporary power solutions.

Technical Specifications

• Capacity: 100-300 tph

• Max. Feed Size: 850 mm

• Jaw Opening: 1100 x 850 mm

• Weight: 52,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

******************************************************************

Standard Features:

• High-capacity jaw crusher unit

• Wheeled mobile chassis

• Hydraulic folding conveyors

• PLC-based control system

• Electric operation

• Gear motor-driven conveyors

• Feed hopper and grizzly vibro feeder

Optional Features:

• Magnetic metal separator

• Hardox-lined hopper

• Automatic lubrication system

• Dust suppression system

Key Features and Differentiators

1. High-Capacity Primary Crushing

The BLJ110 is engineered to deliver consistent primary crushing performance for hard and abrasive stone, ensuring stable throughput and reliable operation in quarrying and mining tasks.

2. Wheeled Mobility

Wheeled design enables fast relocation and setup between job sites, reducing transportation and commissioning time for contractors managing multiple locations.

3. Flexible Integration

The machine can be combined with additional crushers or screens to build multi-chassis mobile plants tailored to project requirements.

4. Operator-Friendly Design

The BLJ110 features intuitive controls, easy maintenance access points, and a straightforward interface to improve operator efficiency and reduce service time.

5. Durable Construction

Built with heavy-duty components, the BLJ110 withstands challenging site conditions and long operational hours while minimizing downtime and maintenance requirements.

6. Enhanced Safety Features

Boratas prioritizes operator safety. The BLJ Series wheeled jaw crusher units are equipped with emergency stop systems, protective guards, and robust structural elements to ensure a safe working environment on site. In addition, the hydraulically adjustable jaw opening further enhances operational safety and control.

Its versatile design supports quick relocation, fast setup, and efficient primary crushing of limestone, granite, basalt, and similar hard materials. The BLJ110 wheeled chassis enables simplified transport between locations, reducing downtime and logistics costs for contractors and quarry operators.

The machine can be integrated into larger wheeled mobile crushing and screening plants, as a two-chassis plant with a cone crusher or as a three-chassis plant with a vertical shaft impact crusher. Which makes it suitable for multi-stage processing systems where compact efficiency and portability are important.

Electric Drive Configuration

The BLJ110 is designed primarily for electric operation and is intended to be connected to an external power source. Upon request, an optional diesel generator can be supplied to support projects requiring independent operation or temporary power solutions.

Technical Specifications

• Capacity: 100-300 tph

• Max. Feed Size: 850 mm

• Jaw Opening: 1100 x 850 mm

• Weight: 52,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

******************************************************************

Standard Features:

• High-capacity jaw crusher unit

• Wheeled mobile chassis

• Hydraulic folding conveyors

• PLC-based control system

• Electric operation

• Gear motor-driven conveyors

• Feed hopper and grizzly vibro feeder

Optional Features:

• Magnetic metal separator

• Hardox-lined hopper

• Automatic lubrication system

• Dust suppression system

Key Features and Differentiators

1. High-Capacity Primary Crushing

The BLJ110 is engineered to deliver consistent primary crushing performance for hard and abrasive stone, ensuring stable throughput and reliable operation in quarrying and mining tasks.

2. Wheeled Mobility

Wheeled design enables fast relocation and setup between job sites, reducing transportation and commissioning time for contractors managing multiple locations.

3. Flexible Integration

The machine can be combined with additional crushers or screens to build multi-chassis mobile plants tailored to project requirements.

4. Operator-Friendly Design

The BLJ110 features intuitive controls, easy maintenance access points, and a straightforward interface to improve operator efficiency and reduce service time.

5. Durable Construction

Built with heavy-duty components, the BLJ110 withstands challenging site conditions and long operational hours while minimizing downtime and maintenance requirements.

6. Enhanced Safety Features

Boratas prioritizes operator safety. The BLJ Series wheeled jaw crusher units are equipped with emergency stop systems, protective guards, and robust structural elements to ensure a safe working environment on site. In addition, the hydraulically adjustable jaw opening further enhances operational safety and control.

أظهر المزيد عرض أقل

معدات ثقيلة

معدات ثقيلة

كرينات

كرينات

مناولة العتاد

مناولة العتاد

الشاحنات والمقطورات

الشاحنات والمقطورات

مركبة تجارية

مركبة تجارية

معدات الزراعية

معدات الزراعية

مزادات مباشرة

مزادات مباشرة