2026 Boratas BPB200

2026 Boratas BPB200

السنة

السنة

٢٠٢٦

حالة المعدة

حالة المعدة

جديد

نظرة عامة

الوصف

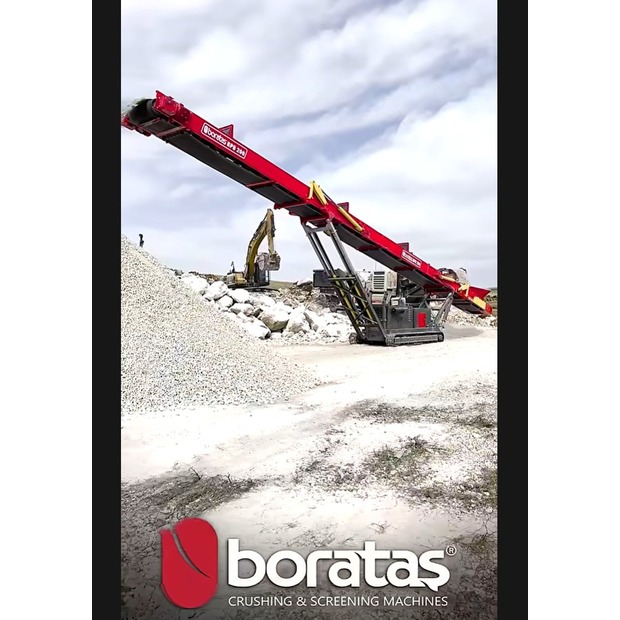

Boratas Tracked Belt Conveyor BPB200 is a fully mobile, high-capacity tracked belt conveyor used for efficient material handling and stockpiling in crushing, screening, and bulk material processing operations. With a production capacity of up to 400–500 tons per hour, the BPB200 supports large-scale projects by streamlining material flow and reducing reliance on wheel loaders for stockpile management, improving overall site efficiency and lowering operating costs.

The BPB200 mobile stacker is commonly used for conveying and stockpiling crushed stone, sand, and gravel from secondary crushers or screening units. It is also suitable for handling industrial waste, biomass, and various construction materials, making it a versatile solution for different material types and site layouts.

Built on a robust track-mounted chassis, the BPB200 combines high throughput with full mobility, allowing easy relocation and flexible positioning across the job site. Its durable structure and adaptable design make it a reliable component of mobile crushing and screening plants operating under demanding site conditions.

Designed to meet different operational requirements, the Boratas BPB200 is available in standard configurations with features that support flexible stockpiling, fast relocation, and reliable operation in challenging environments.

Technical Specifications

• Angle of Conveyor: 12° - 22°

• Stockpile Height: 6,740 - 9,820 mm

• Stockpile Capacity: 565 - 1,746 m³

• Application: Stockpiling and material transfer

• Mobility: Track-mounted

• Setup Time: < 20 minutes (typical)

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

• Track-mounted conveyor chassis

• Hydraulic folding head and tail sections

• Telescopic front and rear sections

• Counter-weighted feed boot

• Hydraulic height adjustment system

• Drum motors

• PLC-based control system

• Integrated mobility and transport system

Key Features and Differentiators

1. High Throughput Capacity

The BPB200 is designed to handle high material volumes, delivering consistent conveying performance while maintaining efficient site logistics and production flow.

2. Enhanced Stockpiling Capability

The extended conveyor length and increased discharge height allow the BPB200 to create larger stockpiles. This reduces material rehandling and improves overall site organization.

3. Cost-Efficient Operation

By minimizing the need for wheel loaders, the BPB200 significantly reduces fuel consumption and operating costs while increasing productivity across the plant.

4. Fast Setup and Mobility

Hydraulic folding mechanisms enable compact transport and quick commissioning. The tracked chassis allows easy repositioning to adapt to changing site requirements.

5. Optimized Operating Angle

Boratas conveyor throughput values are based on a recommended operating angle of 18°, ensuring optimal belt performance and material flow at the stated capacities.

6. Durable Construction

Built for continuous operation in harsh conditions, the BPB200 features a reinforced structure and reliable components that ensure long service life and operational stability.

Boratas Tracked Belt Conveyor BPB200 is a fully mobile, high-capacity tracked belt conveyor used for efficient material handling and stockpiling in crushing, screening, and bulk material processing operations. With a production capacity of up to 400–500 tons per hour, the BPB200 supports large-scale projects by streamlining material flow and reducing reliance on wheel loaders for stockpile management, improving overall site efficiency and lowering operating costs.

The BPB200 mobile stacker is commonly used for conveying and stockpiling crushed stone, sand, and gravel from secondary crushers or screening units. It is also suitable for handling industrial waste, biomass, and various construction materials, making it a versatile solution for different material types and site layouts.

Built on a robust track-mounted chassis, the BPB200 combines high throughput with full mobility, allowing easy relocation and flexible positioning across the job site. Its durable structure and adaptable design make it a reliable component of mobile crushing and screening plants operating under demanding site conditions.

Designed to meet different operational requirements, the Boratas BPB200 is available in standard configurations with features that support flexible stockpiling, fast relocation, and reliable operation in challenging environments.

Technical Specifications

• Angle of Conveyor: 12° - 22°

• Stockpile Height: 6,740 - 9,820 mm

• Stockpile Capacity: 565 - 1,746 m³

• Application: Stockpiling and material transfer

• Mobility: Track-mounted

• Setup Time: < 20 minutes (typical)

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

• Track-mounted conveyor chassis

• Hydraulic folding head and tail sections

• Telescopic front and rear sections

• Counter-weighted feed boot

• Hydraulic height adjustment system

• Drum motors

• PLC-based control system

• Integrated mobility and transport system

Key Features and Differentiators

1. High Throughput Capacity

The BPB200 is designed to handle high material volumes, delivering consistent conveying performance while maintaining efficient site logistics and production flow.

2. Enhanced Stockpiling Capability

The extended conveyor length and increased discharge height allow the BPB200 to create larger stockpiles. This reduces material rehandling and improves overall site organization.

3. Cost-Efficient Operation

By minimizing the need for wheel loaders, the BPB200 significantly reduces fuel consumption and operating costs while increasing productivity across the plant.

4. Fast Setup and Mobility

Hydraulic folding mechanisms enable compact transport and quick commissioning. The tracked chassis allows easy repositioning to adapt to changing site requirements.

5. Optimized Operating Angle

Boratas conveyor throughput values are based on a recommended operating angle of 18°, ensuring optimal belt performance and material flow at the stated capacities.

6. Durable Construction

Built for continuous operation in harsh conditions, the BPB200 features a reinforced structure and reliable components that ensure long service life and operational stability.

The BPB200 mobile stacker is commonly used for conveying and stockpiling crushed stone, sand, and gravel from secondary crushers or screening units. It is also suitable for handling industrial waste, biomass, and various construction materials, making it a versatile solution for different material types and site layouts.

Built on a robust track-mounted chassis, the BPB200 combines high throughput with full mobility, allowing easy relocation and flexible positioning across the job site. Its durable structure and adaptable design make it a reliable component of mobile crushing and screening plants operating under demanding site conditions.

Designed to meet different operational requirements, the Boratas BPB200 is available in standard configurations with features that support flexible stockpiling, fast relocation, and reliable operation in challenging environments.

Technical Specifications

• Angle of Conveyor: 12° - 22°

• Stockpile Height: 6,740 - 9,820 mm

• Stockpile Capacity: 565 - 1,746 m³

• Application: Stockpiling and material transfer

• Mobility: Track-mounted

• Setup Time: < 20 minutes (typical)

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Main Components

• Track-mounted conveyor chassis

• Hydraulic folding head and tail sections

• Telescopic front and rear sections

• Counter-weighted feed boot

• Hydraulic height adjustment system

• Drum motors

• PLC-based control system

• Integrated mobility and transport system

Key Features and Differentiators

1. High Throughput Capacity

The BPB200 is designed to handle high material volumes, delivering consistent conveying performance while maintaining efficient site logistics and production flow.

2. Enhanced Stockpiling Capability

The extended conveyor length and increased discharge height allow the BPB200 to create larger stockpiles. This reduces material rehandling and improves overall site organization.

3. Cost-Efficient Operation

By minimizing the need for wheel loaders, the BPB200 significantly reduces fuel consumption and operating costs while increasing productivity across the plant.

4. Fast Setup and Mobility

Hydraulic folding mechanisms enable compact transport and quick commissioning. The tracked chassis allows easy repositioning to adapt to changing site requirements.

5. Optimized Operating Angle

Boratas conveyor throughput values are based on a recommended operating angle of 18°, ensuring optimal belt performance and material flow at the stated capacities.

6. Durable Construction

Built for continuous operation in harsh conditions, the BPB200 features a reinforced structure and reliable components that ensure long service life and operational stability.

أظهر المزيد عرض أقل

معدات ثقيلة

معدات ثقيلة

كرينات

كرينات

مناولة العتاد

مناولة العتاد

الشاحنات والمقطورات

الشاحنات والمقطورات

مركبة تجارية

مركبة تجارية

معدات الزراعية

معدات الزراعية

مزادات مباشرة

مزادات مباشرة