×

Join our mailing list for regular updates

Crushers & Screens for Sale

We've found 573 listings you may like

Construction

×

Crushers & Screens

×

PREMIUM

2025 Dongmeng DMS620C

New, Crushers & Screens

Shanghai, China

Price

240,750 USD

PREMIUM

2022 Metso ST 2.8

1,604 Hrs, Used, Crushers & Screens

Overijse, Belgium

PREMIUM

2025 Dongmeng DC Series

New, Jaw Crusher

Shanghai, China

PREMIUM

2025 Dongmeng DHP

New, Cone Crusher

Shanghai, China

PREMIUM

2025 Dongmeng Cone Crusher DMC

New, Cone Crusher

Shanghai, China

PREMIUM

2025 Dongmeng Impact Crusher PFW

New, Impact Crusher

Shanghai, China

PREMIUM

2025 Dongmeng PF

New, Impact Crusher

Shanghai, China

PREMIUM

2025 Dongmeng Impact Crusher DVSI

New, Impact Crusher

Shanghai, China

PREMIUM

2025 Dongmeng Cone Crusher DXF

New, Cone Crusher

Shanghai, China

PREMIUM

2025 Dongmeng PEW Series

New, Jaw Crusher

Shanghai, China

PREMIUM

2025 Dongmeng Cone Crusher DHY

New, Cone Crusher

Shanghai, China

Price

53,393 USD

2007 Terra Select T6

12,490 Hrs, Used, Crushers & Screens

Hardenberg, Netherlands

Pegson OTHERS

Used, Crushers

Ireland

2007 MB BF60.1 S4

Used, Crushers

Ireland

Other

Used, Screens

Ireland

2023 Keestrack K6

5 Hrs, Used, Screens

China

2025 Keestrack R6

15 Hrs, New, Crushers

China

2025 Keestrack C6

20 Hrs, New, Screens

China

2023 Terex Finlay 883+

10 Hrs, Used, Screens

China

2017 Keestrack R6

5,500 Hrs, Used, Crushers

China

Other OTHERS

Used, Screens

Ireland

2021 Keestrack R5

2,900 Hrs, Used, Crushers

China

45Kw Electric Motor & Starter

Used, Crushers

Ireland

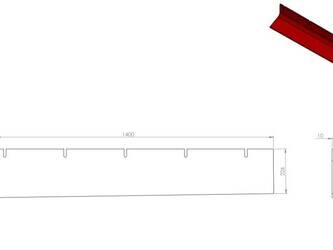

PowerScreen 44x28 Mainframe

Used, Crushers

Ireland

Sandvik QJ340

Used, Crushers

Ireland

Other

Used, Crushers

Ireland

Linde HMV280

Used, Crushers

Ireland

Finlay J-1170

Used, Conveyors

Ireland

Hydraulic Cylinders

Used, Crushers

Ireland

Used & New Conveyor Belts (Large Selection)

Used, Crushers

Ireland

2014 Sandvik QJ341

Used, Grizzly Feeders

Ireland

2019 Sandvik QI341HS

Used, Impact Crusher

Ireland

2014 Sandvik QJ341

3 Hrs, Used, Jaw Crusher

Ireland

ROCO M810

Used, Crushers

Ireland

Share

Construction Equipment

Construction Equipment

Cranes

Cranes

Material Handling

Material Handling

Trucks & Trailers

Trucks & Trailers

Vehicles

Vehicles

Agricultural Equipment

Agricultural Equipment

Live Auctions

Live Auctions