2026 Boratas BLV900-E

Year

Year

2026

Condition

Condition

New

Overview

Description

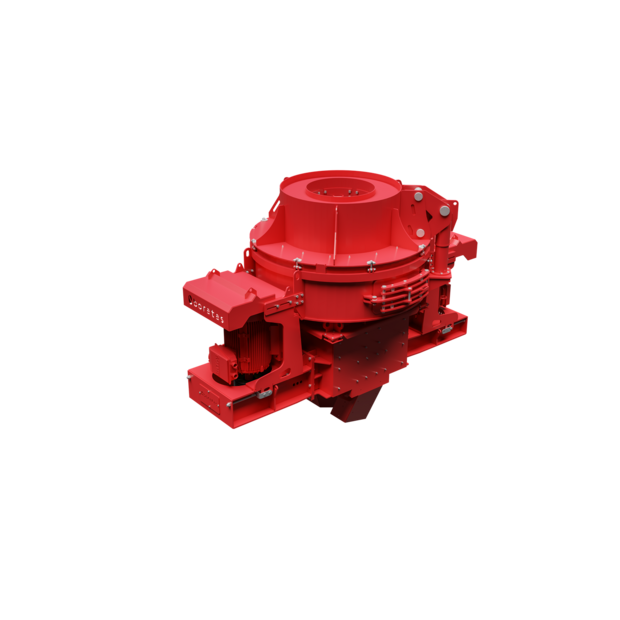

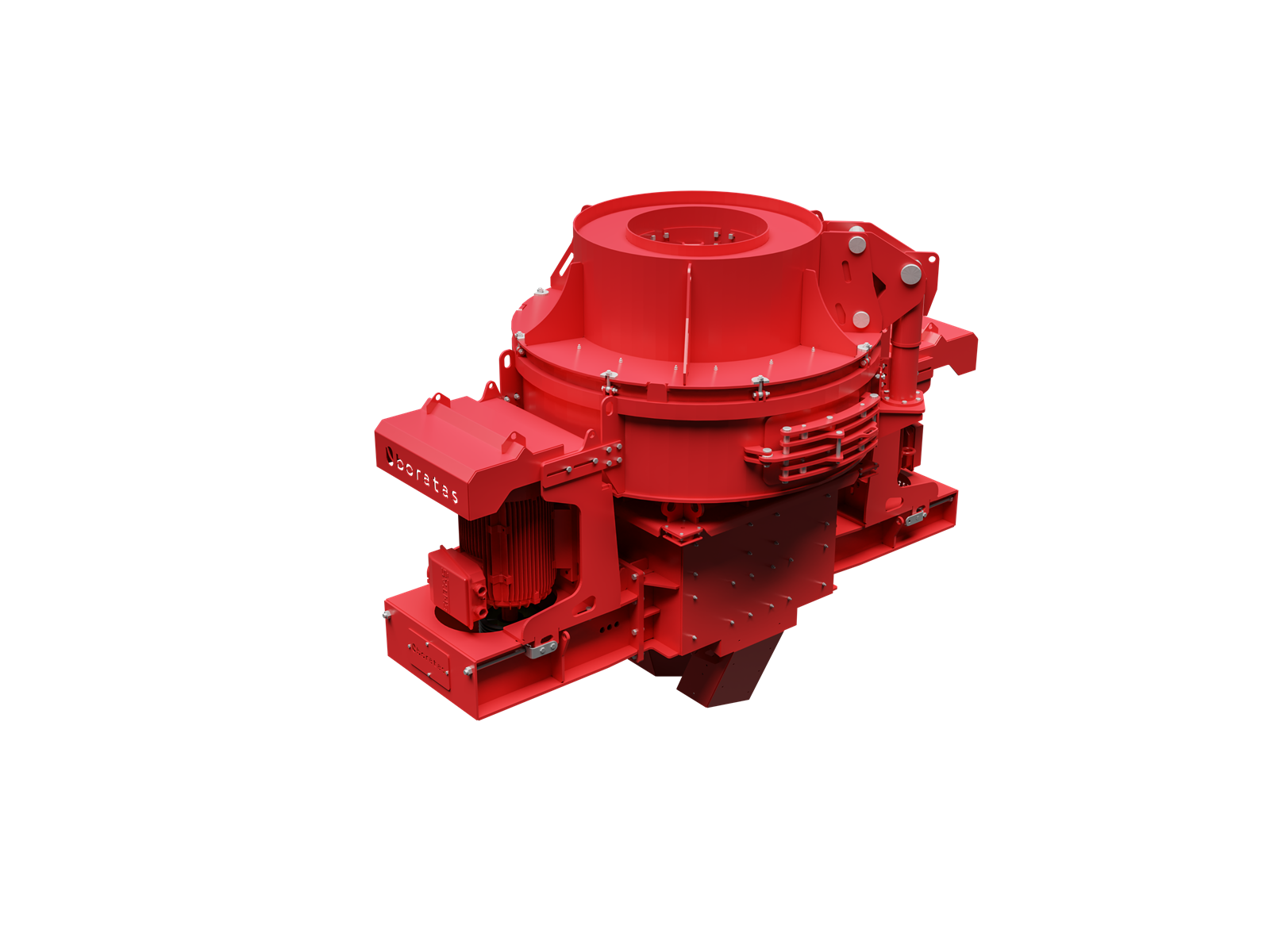

Boratas Wheeled Mobile VSI Crushing and Screening Plant BLV900-E is a semi-mobile vertical shaft impact crusher and screen engineered for the production of high-quality sand and finely graded aggregates. Equipped with a closed-rotor VSI crusher and an integrated vibrating screen on a single wheeled chassis, it delivers fine, cubical materials suitable for concrete, asphalt, and construction applications.

The unit is specifically suited for final-stage crushing where precision shaping and controlled sizing are required. It is typically fed with material up to approximately 38 mm after primary or secondary crushing, enabling accurate processing into fine fractions with reliable classification.

The BLV900-E wheel-mounted VSI crusher plant is optimized for efficient relocation and fast installation compared to fixed plants, helping operators reduce transport and setup costs between project sites. Its compact layout and combined crushing and screening configuration make it suitable for temporary quarries, construction projects, and recycled material facilities where space efficiency and flexible deployment are important.

Electric Drive Configuration

The BLV900-E wheeled vertical shaft impact crusher is designed primarily for electric drive operation and is intended to be connected to an external power source. An optional diesel generator can be supplied on request for projects that require independent or temporary power solutions, enabling flexible operation without compromising performance.

Technical Specifications

Capacity: 200-300 tph

Screen Deck: 3

Max. Feed Size: 38 mm

Rotor Diameter: Ø900

Weight: 54,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Standard Features:

• Closed-rotor vertical shaft impact crusher with high-efficiency crushing performance

• Integrated multi-deck vibrating screening system (3 or 4 deck)

• Wheel-mounted mobile chassis for fast relocation

• Hydraulic folding conveyor belts

• PLC-based control system

• Electric drive operation

• Gear-driven conveyor belts

Optional Features:

• Magnetic metal separator

• Hardox-lined hopper

• Automatic lubrication system

• Dust reduction system

Key Features and Differentiators

1. Integrated VSI Crushing and Screening

The BLV900-E combines a vertical shaft impact crusher with an onboard vibrating screen to produce finely classified material in a single mobile unit, enhancing site productivity and reducing handling steps.

2. Wheeled Mobility for Fast Deployment

Mounted on a wheeled chassis, this VSI crusher and screener plant is easy to transport and set up on site, supporting projects that require frequent relocation or temporary installation.

3. Fine Material Production

Designed to produce materials in the 0–5 mm range with excellent cubical shape, the BLV900-E is well-suited for sand production, concrete aggregate, and other applications requiring precise final grading.

4. User-Friendly Operation

Intuitive controls, straightforward maintenance access, and simplified adjustment points help reduce downtime and improve operator efficiency on site.

5. Electric Drive with Optional Power Support

Electric operation helps lower running costs and onsite emissions. When needed, an optional generator can be provided to support off-grid or temporary power requirements without sacrificing crushing or screening performance.

6. Durable Design for Continuous Use

Built with robust components and industrial-grade materials, the BLV900-E supports long operational life and dependable performance under diverse working conditions.

Boratas Wheeled Mobile VSI Crushing and Screening Plant BLV900-E is a semi-mobile vertical shaft impact crusher and screen engineered for the production of high-quality sand and finely graded aggregates. Equipped with a closed-rotor VSI crusher and an integrated vibrating screen on a single wheeled chassis, it delivers fine, cubical materials suitable for concrete, asphalt, and construction applications.

The unit is specifically suited for final-stage crushing where precision shaping and controlled sizing are required. It is typically fed with material up to approximately 38 mm after primary or secondary crushing, enabling accurate processing into fine fractions with reliable classification.

The BLV900-E wheel-mounted VSI crusher plant is optimized for efficient relocation and fast installation compared to fixed plants, helping operators reduce transport and setup costs between project sites. Its compact layout and combined crushing and screening configuration make it suitable for temporary quarries, construction projects, and recycled material facilities where space efficiency and flexible deployment are important.

Electric Drive Configuration

The BLV900-E wheeled vertical shaft impact crusher is designed primarily for electric drive operation and is intended to be connected to an external power source. An optional diesel generator can be supplied on request for projects that require independent or temporary power solutions, enabling flexible operation without compromising performance.

Technical Specifications

Capacity: 200-300 tph

Screen Deck: 3

Max. Feed Size: 38 mm

Rotor Diameter: Ø900

Weight: 54,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Standard Features:

• Closed-rotor vertical shaft impact crusher with high-efficiency crushing performance

• Integrated multi-deck vibrating screening system (3 or 4 deck)

• Wheel-mounted mobile chassis for fast relocation

• Hydraulic folding conveyor belts

• PLC-based control system

• Electric drive operation

• Gear-driven conveyor belts

Optional Features:

• Magnetic metal separator

• Hardox-lined hopper

• Automatic lubrication system

• Dust reduction system

Key Features and Differentiators

1. Integrated VSI Crushing and Screening

The BLV900-E combines a vertical shaft impact crusher with an onboard vibrating screen to produce finely classified material in a single mobile unit, enhancing site productivity and reducing handling steps.

2. Wheeled Mobility for Fast Deployment

Mounted on a wheeled chassis, this VSI crusher and screener plant is easy to transport and set up on site, supporting projects that require frequent relocation or temporary installation.

3. Fine Material Production

Designed to produce materials in the 0–5 mm range with excellent cubical shape, the BLV900-E is well-suited for sand production, concrete aggregate, and other applications requiring precise final grading.

4. User-Friendly Operation

Intuitive controls, straightforward maintenance access, and simplified adjustment points help reduce downtime and improve operator efficiency on site.

5. Electric Drive with Optional Power Support

Electric operation helps lower running costs and onsite emissions. When needed, an optional generator can be provided to support off-grid or temporary power requirements without sacrificing crushing or screening performance.

6. Durable Design for Continuous Use

Built with robust components and industrial-grade materials, the BLV900-E supports long operational life and dependable performance under diverse working conditions.

The unit is specifically suited for final-stage crushing where precision shaping and controlled sizing are required. It is typically fed with material up to approximately 38 mm after primary or secondary crushing, enabling accurate processing into fine fractions with reliable classification.

The BLV900-E wheel-mounted VSI crusher plant is optimized for efficient relocation and fast installation compared to fixed plants, helping operators reduce transport and setup costs between project sites. Its compact layout and combined crushing and screening configuration make it suitable for temporary quarries, construction projects, and recycled material facilities where space efficiency and flexible deployment are important.

Electric Drive Configuration

The BLV900-E wheeled vertical shaft impact crusher is designed primarily for electric drive operation and is intended to be connected to an external power source. An optional diesel generator can be supplied on request for projects that require independent or temporary power solutions, enabling flexible operation without compromising performance.

Technical Specifications

Capacity: 200-300 tph

Screen Deck: 3

Max. Feed Size: 38 mm

Rotor Diameter: Ø900

Weight: 54,000 kg

Manufactured in compliance with international quality standards.

Supported by Boratas warranty and after-sales service.

For further technical details and project-specific solutions, kindly visit our website:

https://www.boratasglobal.com/en

*******************************************************************

Standard Features:

• Closed-rotor vertical shaft impact crusher with high-efficiency crushing performance

• Integrated multi-deck vibrating screening system (3 or 4 deck)

• Wheel-mounted mobile chassis for fast relocation

• Hydraulic folding conveyor belts

• PLC-based control system

• Electric drive operation

• Gear-driven conveyor belts

Optional Features:

• Magnetic metal separator

• Hardox-lined hopper

• Automatic lubrication system

• Dust reduction system

Key Features and Differentiators

1. Integrated VSI Crushing and Screening

The BLV900-E combines a vertical shaft impact crusher with an onboard vibrating screen to produce finely classified material in a single mobile unit, enhancing site productivity and reducing handling steps.

2. Wheeled Mobility for Fast Deployment

Mounted on a wheeled chassis, this VSI crusher and screener plant is easy to transport and set up on site, supporting projects that require frequent relocation or temporary installation.

3. Fine Material Production

Designed to produce materials in the 0–5 mm range with excellent cubical shape, the BLV900-E is well-suited for sand production, concrete aggregate, and other applications requiring precise final grading.

4. User-Friendly Operation

Intuitive controls, straightforward maintenance access, and simplified adjustment points help reduce downtime and improve operator efficiency on site.

5. Electric Drive with Optional Power Support

Electric operation helps lower running costs and onsite emissions. When needed, an optional generator can be provided to support off-grid or temporary power requirements without sacrificing crushing or screening performance.

6. Durable Design for Continuous Use

Built with robust components and industrial-grade materials, the BLV900-E supports long operational life and dependable performance under diverse working conditions.

Show more Show less

Construction Equipment

Construction Equipment

Cranes

Cranes

Material Handling

Material Handling

Trucks & Trailers

Trucks & Trailers

Vehicles

Vehicles

Agricultural Equipment

Agricultural Equipment

Live Auctions

Live Auctions